Our Team

Our Experts and Engineers

Dr. Naresh Aluri, MBA

Aerothermal Expert

15 years of experience in combustion system development, integration, product lifecycle management & product market introduction.

Experienced in developing & field implementing fuel flexible, clean combustion technologies for various gas turbine types following circular principles, inventor on 12 patents.

Andre Theurer

Design Expert

15 years of experience in combustion system development, mechanical design, manufacturing, integration and product lifecycle management.

Experienced in developing & manufacturing of efficient and clean combustion technologies using newest manufacturing methods as SLM. Inventor on 20 patents.

Dr. Klaus Dobbeling

Business Development

35 years experience in combustion technology, 31 years in GT industry (ABB, Alstom, GE, Ansaldo) focus on product development very large GTs (>400MWel) at Ansaldo Switzerland.

Dr. Reddy Alemela

Aerothermal Expert

Several years of experience in aerothermal layout, Modelling, testing and validation of prototype gas turbine combustor hardware, upgrades on field engines.

Further interested in developing future low emission combustion technologies/systems and active collaboration with respective competence centres.

Suresh MVT

Technology Lead

Decade long experience in turbomachinery, performance, aerodynamics, and flow field measurement and aerothermal layout of radial machines.

Experienced in design & developing of radial compressor, turbine and combustors for micro gas turbine, system design, integration and prototype testing of small gas turbine.

Rahul Singh Chauhan

Senior Engineer

7 years of experience in design, analysis, and optimization of mechanical components.

He has been involved with stress and vibration analysis, rotor dynamics, gas-foil bearing development, fatigue and creep analysis, modal testing, and optimization.

Dr. Raju Murugan

Aerothermal & validation Engineer

Research experience in atomization and sprays, swirl stabilized liquid and gaseous fuel combustion. Experience in Laser Diagnostics for fluid mechanics, combustion applications.

Design and development of the experimental facilities for the various lab scaled burner for liquid and gaseous fuel combustion. Experimentation and data analysis.

Chetan KS

Design Engineer

Around 5 + years of experience in areas of design and analysis, production and new product development. Good knowledge on UG/NX across various modules like 3D modelling, sheet metal drafting and assembly.

Rich experience in design of BIW for Mercedes Benz trucks, migration of surface models, sheet metal models, casting models and plastic models as per MBRDI standards.

Products we offer

Proven track record with state of the art technology

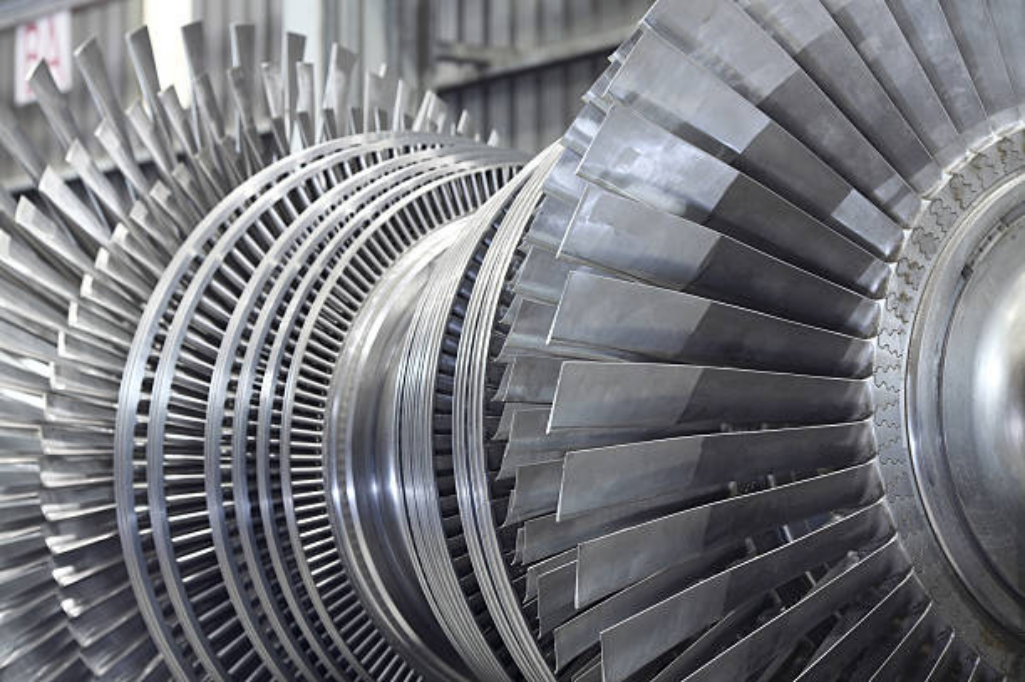

Fuel flexible Burners

Burners available for multi-fuel and for multi-stage.

Optimized Design using Computational methods

Optimal operational performance

Easy system integration

3D-printed high performance materials

SBES-500

The SBES-500 produces 500 N thrust. The turbine utilizes the latest 3D printing technology. Reduces the parts count significantly.

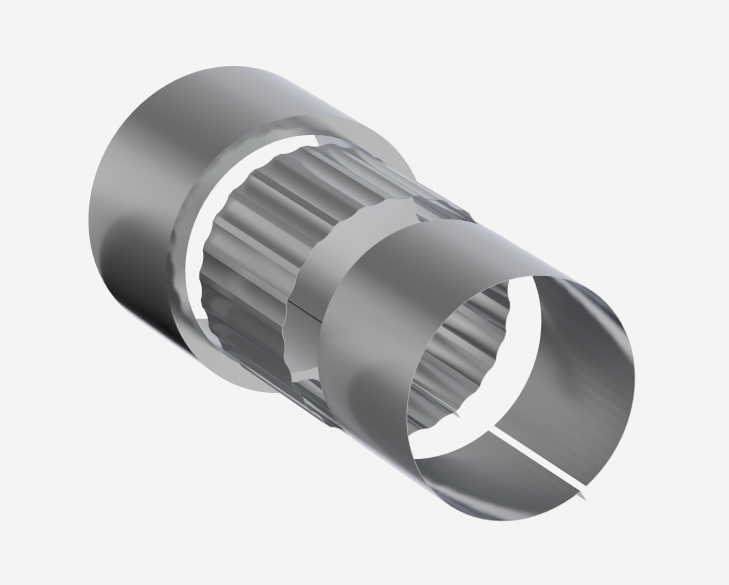

Gas Foil Bearing

Suitable for high RPM machines. Allows high temperature operation of gas turbines. Suitable for high speed turbo-compressors.

The projects we delivered

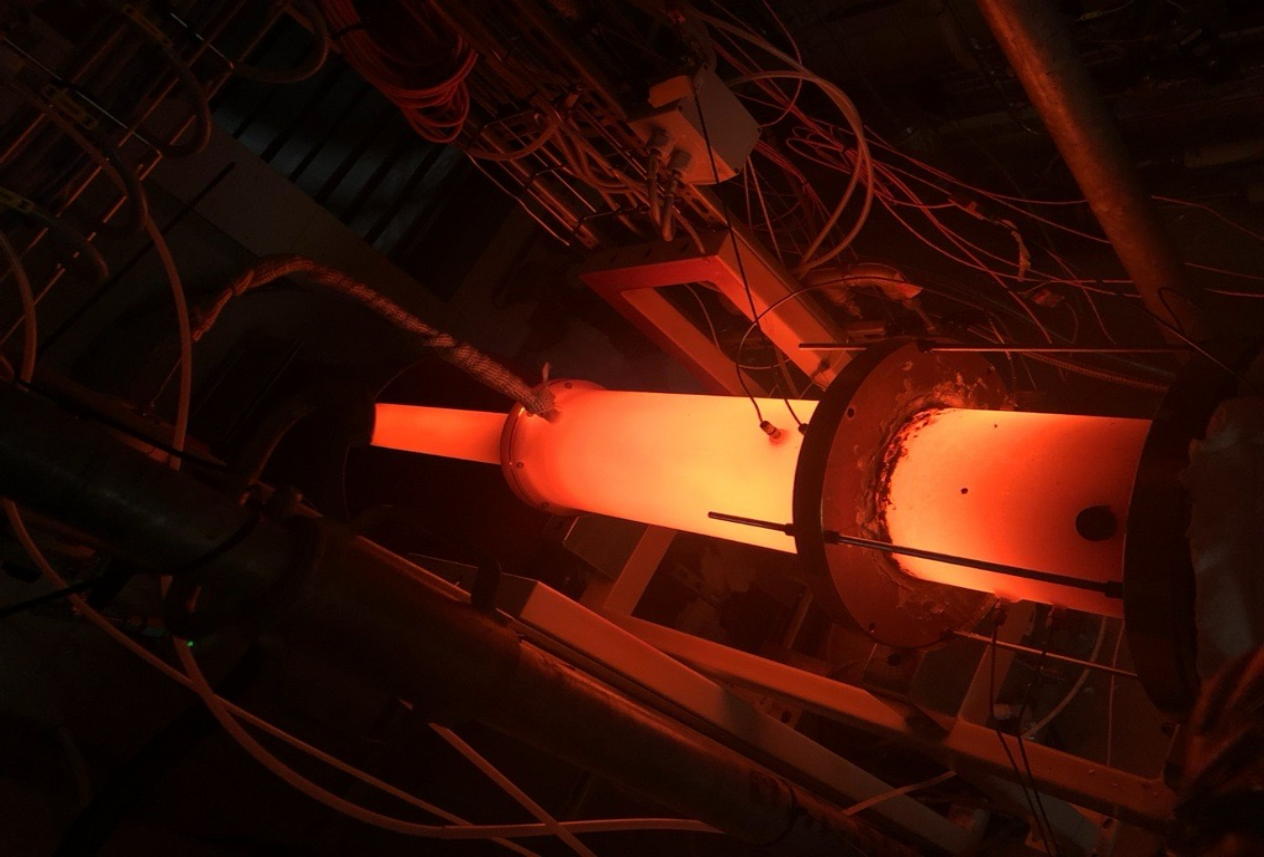

Full System Integration

We test our products to the extreme. The test for the industrial burner of 1MW is running on pure Hydrogen.

Industrial Burner

Due to the recent demand from industries, we created a fuel-flexible burner that can switch between Hydrogen and LPG.

Fuel-flex Burner

Air-fuel mixing is important for efficient combustion. This efficient burner provides efficient mixing and is multi-purpose.

Furnaces

Recent demands for efficient burners for industrial burners forced us to design a burner for industrial furnaces.

Customers and Collaborators

Contact Us

We are just one call away

Sustainable Business & Engineering Solutions GmbH

Bachstrasse 14A

5417 Unterslggenthal

Email Us: info@sbestechnologies.com

Contact Us: +41 798198565

2025. All rights reserved.

©SBES Technologies